概述

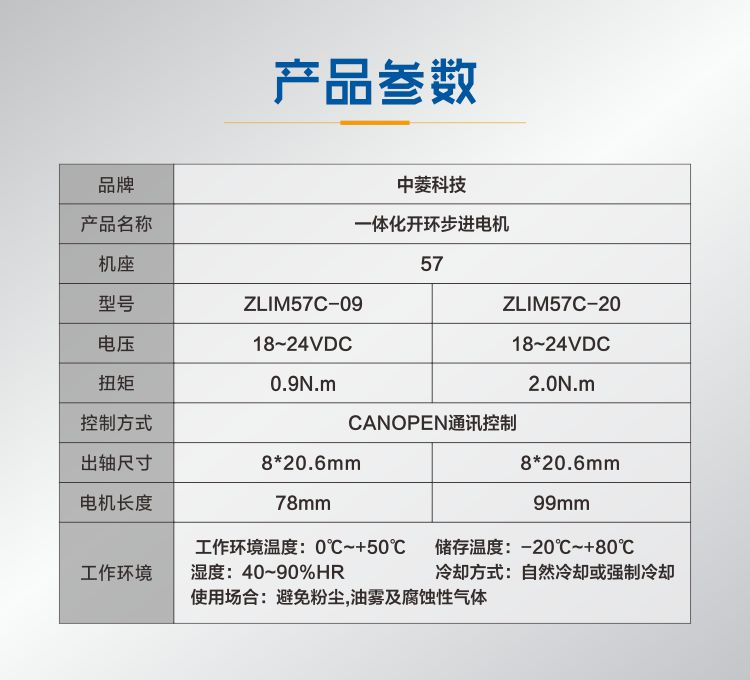

ZLIM57-C 为高性能数字式集成驱动一体的两相混合式开环电机,系统结构简单,集成度高,增加了总线通讯及单轴控制器功能。总线通讯采用 CAN总线接口,协议上支持 CANopen 协议的 CiA301 及 CiA402 子协议。

特点

■ 超低振动和低噪声;

■ 采用 CAN 总线通讯,支持 CANopen 协议的 CiA301 及 CiA402 子协议,最多可挂载 16 个设备;

■ CAN 总线通讯波特率默认 500Kbps;

■ 支持位置控制、速度控制和回原点等工作模式。

■ 用户可以通过总线设置起始速度、加速时间、减速时间、最大速度及总脉冲数等参数实现梯形加减速位置控制功能,具有回原点等功能。

■ 用户可以通过总线设置电流、细分及锁机电流大小;控制电机启停及对电机运行实时状态进行查询。

■ 输入电压:24VDC;

■ 4 隔离信号输入口,可编程,实现驱动器使能、 启停、 急停和限位等功能;

■ 2 隔离输出口,可编程,输出驱动器状态及控制信号;

■ 4 拨码开关选择,16 档物理地址;

■ 具有过压、过流等保护功能;

应用领域

适合各种小型自动化设备和仪器,例如:气动打标机、贴标机、割字机、激光打标机、绘图仪、小型雕刻机、数控机床、拿放装置等。在用户期望小噪声、低振动、高平稳性、高精度的设备中应用效果特佳。

Mailbox:sales@zlingkj.com

Office address:303, 3rd Floor, Building B, Fenghuang Zhigu, Tiezi Road, Xixiang Street, Bao'an District, Shenzhen

Factory address:7th Floor, Building 1, XinLiKang LeChuangLi Smart Industry Park, No. 106 Changdong Road, Changping Town, Dongguan City, Guangdong Province, 523570.